The National Academy of Sciences of Ukraine

National Science Center "Kharkov Institute of Physics and Technology"

"Nuclear Fuel Cycle" Science and Technology Establishment

The National Academy of Sciences of Ukraine

National Science Center "Kharkov Institute of Physics and Technology"

"Nuclear Fuel Cycle" Science and Technology Establishment

Westinghouse fuel fabrication facility in Sweden

|

Checking Westinghouse fuel assemblies after shipping

|

|

Radiation control

|

Attaching stabilizer bars to the fuel assembly strongback and uprighting the strongback with Westinghouse fuel assemblies

|

|

Checking beading on the bolts attaching guide thimbles to the Westinghouse fuel assembly bottom nozzle

|

Visual inspection of fuel rod axial position difference

|

|

Checking Westinghouse fuel assembly geometry in the envelope

|

Checking a fresh Westinghouse fuel assembly's bottom end plug level

|

|

|

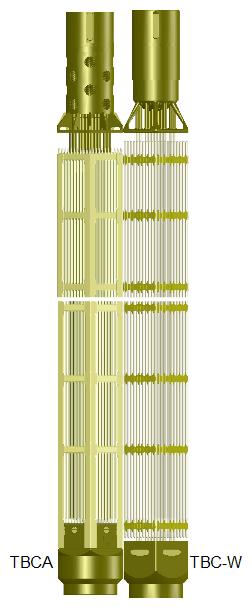

Comparison of the TVSA and Westinghouse designs