Sector's Main Areas of Activity:

-

Develop and research fuel and absorber materials for nuclear facilities of various purposes.

-

Develop design of fuel and absorber elements and their assemblies (FA, RCCA, absorber inserts) for nuclear facilities of various purposes (NPP, nuclear research facilities, neutron source sub-critical assembly).

-

Develop processes to manufacture fuel and absorber materials for the developed fuel and absorber elements.

-

Develop processes to manufacture fuel and absorber elements and their assemblies.

-

Manufacture prototypes and pilot batches of the developed products for out-of-pile tests, and for testing and commercial operation in the operating nuclear facilities.

-

Research the developed products following the tests.

-

Develop advanced (engineering) and executive designs for the developed products.

Sector's Equipment

1 Equipment for Development of Nuclear Fuel Materials (Fuel Pellets and Fuel Particles)

|

Vibrating sieving machine with a sieve column

|

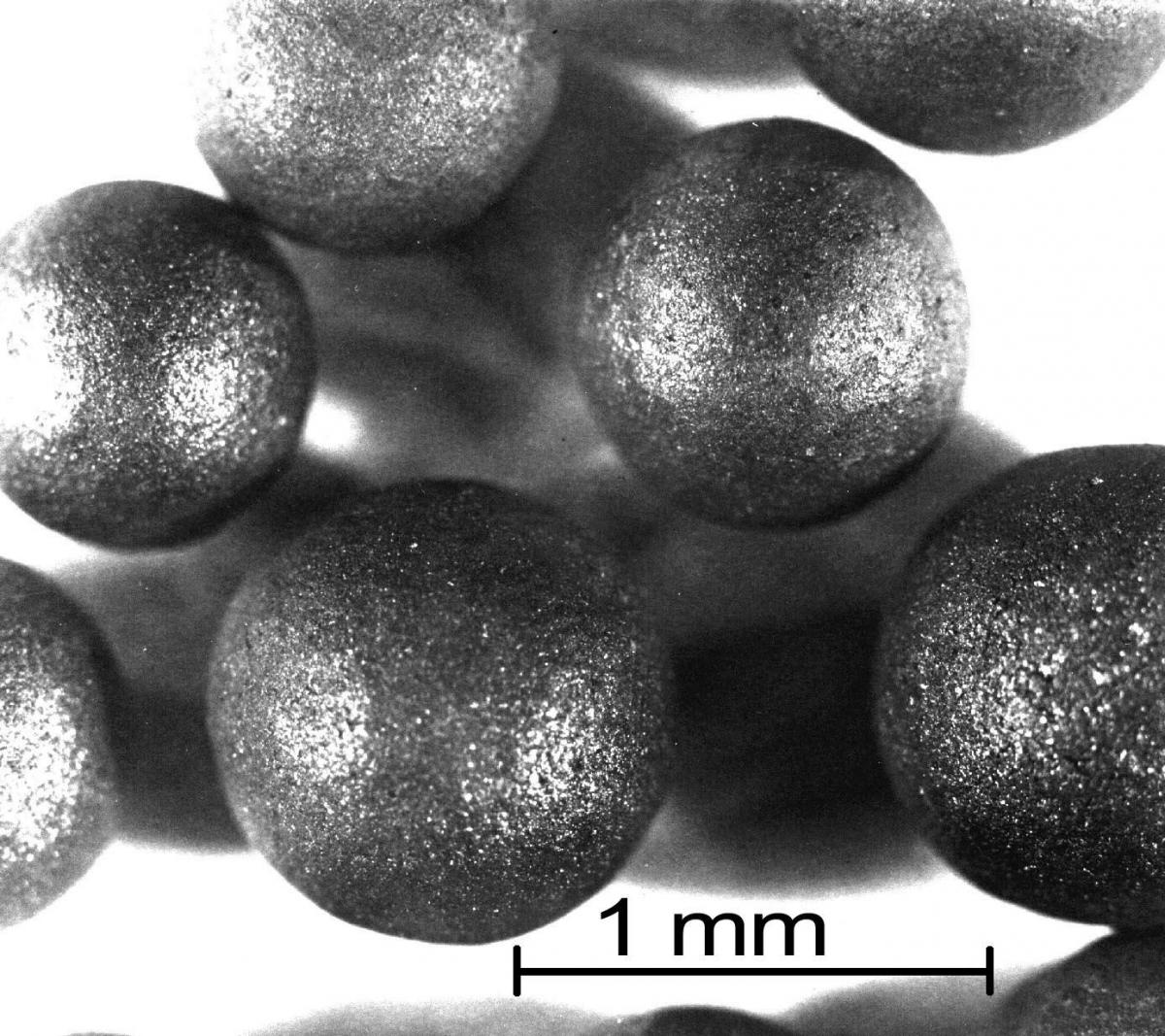

Fuel microsphere spheroidizer

|

|

Hydraulic press for fuel pellet compacting

|

Centerless grinding machine for lateral grinding of fuel pellets

|

2 Equipment for Development of Fuel and Absorber Elements and Their Assemblies

|

Electric-resistance welding machine for fuel rod sealing

|

Machine for electric arc welding with a nonconsumable electrode in an atmosphere of shielding gas for fuel and absorber rod sealing

|

|

Electron-beam welding machine for fuel rod sealing

|

Mass-spectrometry facility for control of fuel and absorber rod pressurization using a helium leak detector and vacuum chambers

|

|

Fuel microspheres

|

WWER pellet fuel

|

|

Fragments of the matrix fuel developed for the sub-critical assembly fuel rods

|

Vertical cross-section of the developed fuel rod with fuel microspheres in a silumin matrix

|

|

Absorber elements for absorber inserts of the ventilated storage containers at Zaporizhya NPP Spent Nuclear Fuel Dry Storage Facility

|

Research into interaction of fuel composition with structural materials

|

The NFC STE Sector for Fuel Elements has been maintaining the developed technologies and equipment in running order and conducting research and development for new areas of activities:

- Development of absorber rods for the WWER-1000 RCCA.

- Optimization of technological operations to manufacture WWER-1000 fuel rods as part of preparation for scientific support of establishment and operation of Ukraine's nuclear fuel fabrication facility.

- Development of design and technologies to manufacture fuel rods and fuel assemblies for the neutron source sub-critical assembly.

- Developed and implemented the project on absorber inserts for the ventilated storage containers at Zaporizhya NPP Spent Nuclear Fuel Dry Storage Facility used for transfer of the spent FAs from the storage pool to the spent nuclear fuel dry storage facility.

- Activities to study lava-like fuel-containing masses formed during accidents with WWER-1000 reactor core meltdown.

- Implementation of ZNPP orders for fabrication of absorber elements for the ventilated storage containers of the spent nuclear fuel dry storage facility. In 2009-2012 about 200 sets of absorber elements for the absorber inserts have been manufactured (3600 absorber elements).

NFC STE Developments That Involved the Sector under Different Contracts

-

Development of absorber materials and absorber element structures for the upgraded RCCA with a combined absorbers В4С+hafnium and В4С+dysprosium hafnate.

-

Development of enhanced fuel materials for power and research nuclear facilities.

-

Technological process for absorber element manufacturing Drawing 12-1-005.01 SB for the Absorber Insert of Ventilated Storage Containers of the Spent Nuclear Fuel Dry Storage Facility, Customer Zaporizhya NPP, 2005-2007.

-

Development of design, selection of technologies and performance substantiation of enhanced reliability absorber rods with combined absorber materials for the reactor rod control cluster assemblies of power reactors, Customer – National Academy of Sciences of Ukraine (NASU), Task 10 of the NASU Nuclear Materials and Radiation Technologies Program “Nuclear, Thermal Physical, and Material Science Research to Substantiate Safety, Performance, Economic Efficiency, and Optimum Conditions for Operation of Current and Future Reactor Cores in Ukraine”. (2007-2008)

-

Development of advanced (engineering) design for absorber inserts for spent fuel assemblies in ventilated storage containers of spent nuclear fuel dry storage facilities. Customer Zaporizhya NPP, Contract 65/07. 2007

-

Development of a proposal to organize a manufacturing floor for absorber elements of absorber inserts for the ventilated storage containers of the spent nuclear fuel dry storage facility at Zaporizhya NPP. Customer Atomenergomash of NNEGC Energoatom. 2010-2011

-

Transfer and follow-up of the NFC STE NSC KIPT technology of manufacturing absorber elements for the ventilated storage containers of the spent nuclear fuel dry storage facility at Zaporizhya NPP. Customer Atomenergomash of NNEGC Energoatom. 2011

-

Absorber insert for ventilated storage containers of spent nuclear fuel dry storage facilities, Technical Specification, 12-1-005.00 TU, 2008.

-

Fabrication of pilot batches of absorber elements for the ventilated storage containers of the spent nuclear fuel dry storage facility at Zaporizhya NPP (504 items, Contract 70/08).

-

Fabrication of the commercial batch of absorber elements for the ventilated storage containers of the spent nuclear fuel dry storage facility at Zaporizhya NPP (504 items, Contract 91/11, 2011).

-

Development of a technical proposal on fuel composition and design of fuel rods and fuel assembly for the sub-critical assembly, and their manufacturing technologies for the nuclear facility “Neutron Source Based on the Accelerator Driven Sub-Critical Assembly”; STCU Project 233 (2007-2009).